Recovering heat from the refrigeration process…

Fabdec has pioneered heat transfer technology in stainless steel since 1960, producing vessels for all industries in our UK manufacturing facility.

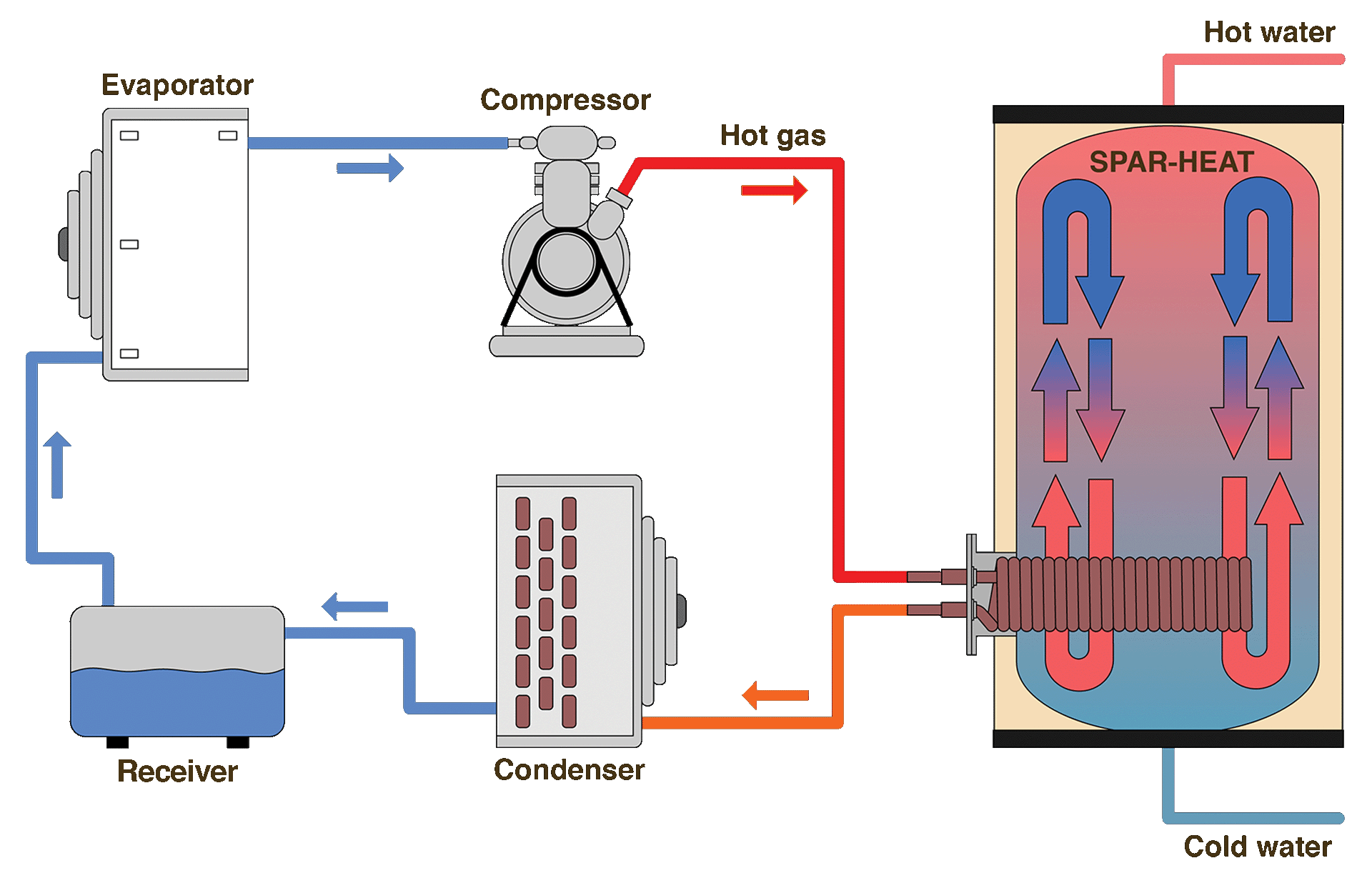

Every refrigeration system is effectively a heat pump. The refrigerant changes state during the cooling process and the compressor creates an excess of waste heat, which is rejected into the atmosphere.

The goal of heat recovery is to capture this waste heat and convert it into free hot water.

SPAR-HEAT is a durable stainless steel cylinder with double-walled spiral heat exchangers designed to recover the waste heat in a safe and efficient manner, generating hot water at temperatures of up to 60°C.

Immersion heaters can then boost it up to 85°C.

Stainless steel cladding is also an alternative for outdoor installation.

SPAR-HEAT Overview

- 130L – 3000L range

- Multiple heat exchanger coil options

- Durable duplex stainless steel

- Little maintenance as without moving parts

- Market-leading insulation with CFC-free polyurethane foam

- Safe potable water protection thanks to secure double wall heat exchange

- Hygienic scratch-resistant plastisol cladding

- Immersion bosses for boosting water temperature

How SPAR-HEAT fits into the refrigeration circuit

Heat Exchanger Coil

The heat exchanger consists of an outer tin-plated spirally wound high-finned tube, and an inner (refrigerant side) copper tube. The double-walled structure prevents the possibility of drinking water from mixing with refrigerant oil, meeting DIN standards EN12897 and PD5500.

We also manufacture custom-made thermoplates…

Using our state-of-the-art laser heat exchanger plate welding machine, the only one of its type in the UK, we can manufacture plates to the optimum efficient design for heating or cooling.

These are supplied as single plates or as manifolded assemblies.

Energy Blades – Water Based Heat Recovery

Designed for locations with freshwater lakes, rivers, ponds and streams, the Energy Blade is another brilliant energy saving solution.

Water is the best medium for energy retention, Energy Blades working in conjunction with ground source heat pumps offer a complete renewable energy system.

With no ground work required, installation is minimal and cost effective.

Our plates are made up of a pre-assembled stainless steel bank with an integral manifold, standard dimensions are 3000mm X 500mm X 800mm although bespoke options are available and alternative grades of material (304/316). Multiple banks can be connected to increase the capacity.

The Energy Blade can free-stand on a suitable solid base or be positioned under jetties, landing stages and bridges.

OUR OTHER PRODUCTS

DAIRY

Read More

WATER HEATING

Read More

PROCESS VESSELS

Read More

SPARES

Read More