Falling Film Chillers

Built in Britain, our falling film chiller delivers rapid, energy-efficient cooling with unmatched reliability, compact design, and long-lasting stainless-steel construction.

✔ Variable Sizes

✔ Bespoke Design

✔ Stainless Steel

✔ Low Freeze Risk

✔ Low Maintenance

✔ British Quality

What Are Falling Film Chillers?

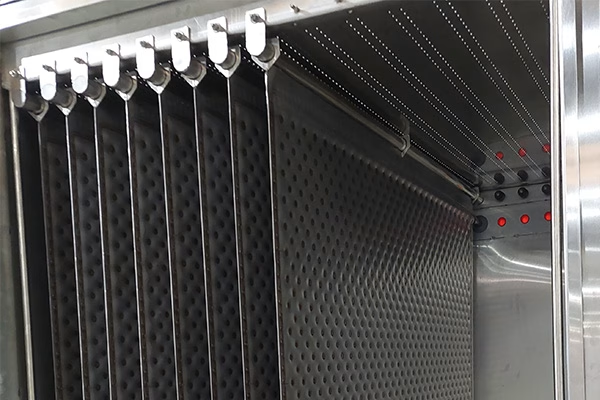

A falling film chiller is an advanced cooling system designed to achieve rapid, reliable, and precise temperature control through highly efficient heat exchange. At Fabdec Dairy Systems, our engineers design and build each unit in Britain using durable stainless steel, which guarantees strength, hygiene, and long-term performance in every application.

Unlike traditional pre-cooling alternatives, these systems evenly distributes coolant over vertical pillow plates, enabling faster heat removal, superior consistency, and uniform cooling across all contact surfaces. Because of this even flow, the system eliminates freezing risk while maintaining exceptional energy efficiency. Moreover, its compact, space-saving design integrates easily within both new and existing production lines, providing seamless adaptability across dairy, beverage, and industrial processing facilities.

Fabdec custom-builds every falling film chiller, offering between two and fourteen pillow plates to match specific cooling capacities. Each unit delivers reliable, energy-efficient operation with minimal maintenance and low running costs. Additionally, every system incorporates advanced design features that optimise heat transfer, reduce energy consumption, and enhance process control. Our engineers also ensure that each model supports sustained performance, maximising productivity, protecting product quality, and promoting sustainable manufacturing goals throughout daily operations.

Designed for Performance

Fabdec’s falling film chiller delivers exceptional cooling performance through advanced pillow plate technology. Each system ensures rapid heat transfer and accurate temperature control, providing dependable results across every application. Because coolant flows evenly over the plates, cooling remains uniform while preventing freezing or inefficiency during production.

Furthermore, stainless steel construction guarantees hygiene, strength, and low maintenance. As a result, every unit offers consistent performance with minimal energy use. Whether installed in dairy or beverage processing, the unit operates efficiently, day after day. Its combination of speed, stability, and durability ensures reliable temperature management while keeping operating costs low.

Built to Last, Made in Britain

Every falling film chiller is proudly manufactured in Britain, where precision engineering meets long-term reliability. Each unit is crafted from high-quality stainless steel for outstanding corrosion resistance and strength. Because Fabdec fabricates every component in-house, quality control remains consistent throughout production, ensuring each system exceeds performance expectations.

Moreover, our skilled engineers continually refine designs to enhance durability and efficiency. Consequently, the system maintains exceptional reliability even under heavy industrial use. Customers choose Fabdec because we deliver long-lasting performance supported by genuine British craftsmanship. Built with care, every chiller represents our commitment to quality, value, and dependable operation for years to come.

Customisable for Any Application

Each falling film chiller from Fabdec Dairy Systems is custom-built to suit specific process requirements. With a choice of two to fourteen pillow plates, cooling capacity can be tailored precisely to your production needs. Because design and fabrication occur entirely in-house, every detail, from fittings to flow configuration is optimised for the intended application.

As a result, the unit integrates seamlessly into any system, delivering consistent cooling performance across diverse environments. Whether you operate a dairy, brewery, or process plant, our flexible design approach ensures a perfect fit. Furthermore, this adaptability improves efficiency and reliability, providing you with a cooling solution that grows with your business.

Efficiency That Reduces Costs

Every Fabdec falling film chiller is engineered for long-term efficiency. Its innovative design maximises heat transfer while preventing freezing, ensuring steady cooling performance under continuous operation. Because energy is used effectively, the system maintains precise temperature control without unnecessary power consumption.

Additionally, the low-maintenance construction minimises downtime, keeping production consistent and costs under control. Over time, these efficiency gains translate into substantial savings in both energy and servicing. Furthermore, reliable operation safeguards product quality and process stability, giving operators complete confidence in daily performance. Choosing a Fabdec falling film chiller means investing in technology that delivers sustainability, savings, and reliability.